Turkey

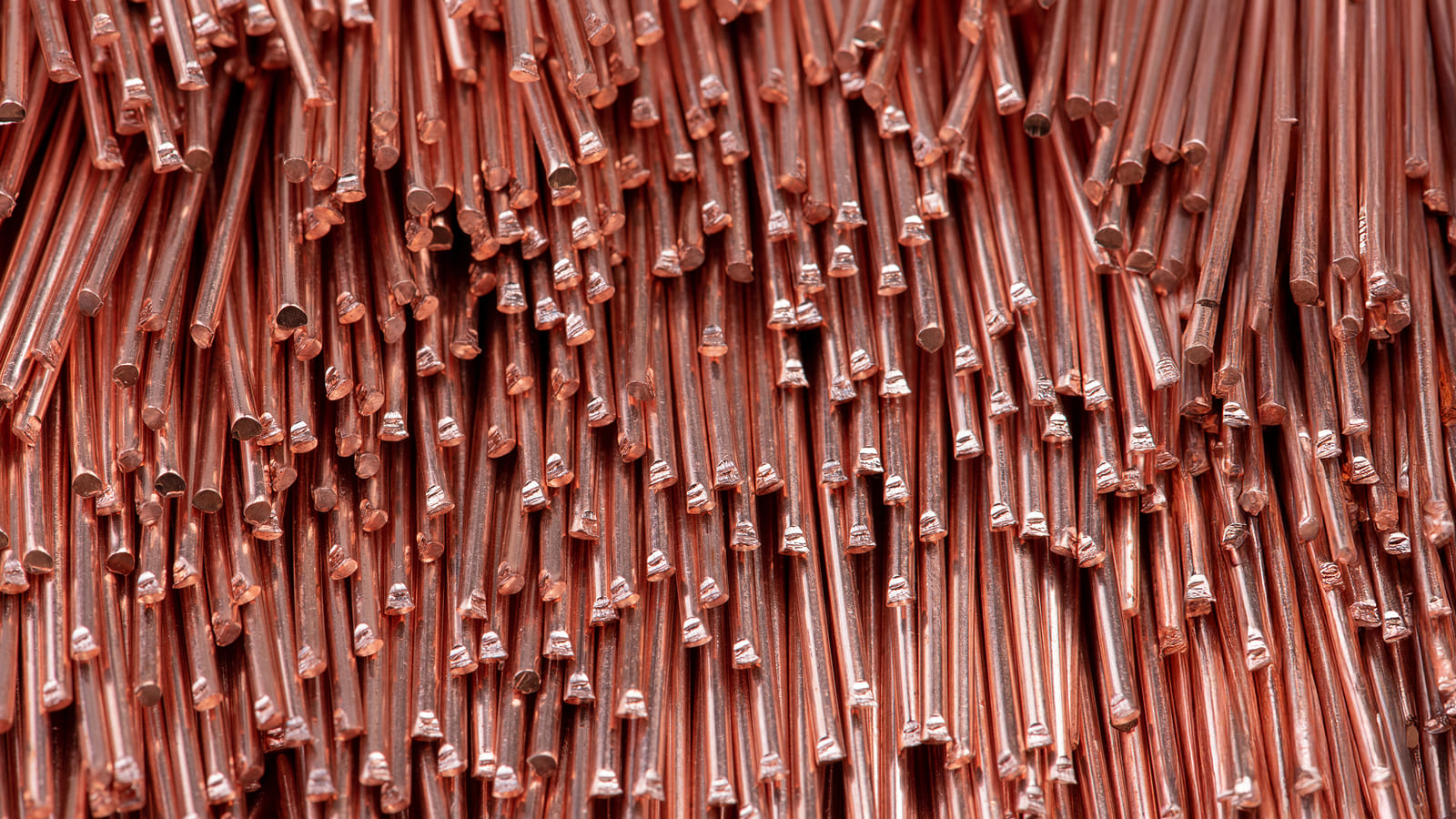

We responsibly develop and operate mines across the world, providing materials that are vital to society.

Mining is an industry revolutionized by innovative engineering, finding new ways to safely and responsibly make the most of any project whilst simultaneously minimizing the risks for the people involved, for the surrounding communities and for our planet.

We take our own approach when it comes to creating and running mines. We don’t use external contractors. This means we have the opportunity to learn and improve on every aspect of our operations – helping us to create and operate mines that bring more value to society.

We also understand that each operation and each project is different, which is why we employ experts at every level and empower them to make decisions, because the people closest to the action are the ones that understand the important nuances at play.

Our operations and development projects span diverse conditions across five continents. Visit each location to find out more about our mineral producing assets and new prospects.

Turkey

Spain

Panama

Zambia

Mauritania

Peru

Zambia

Peru

Finland

Australia

Zambia

Argentina

We both develop and operate our projects and mines. We don’t use external contractors. Because we operate what we’ve built, we learn and improve on every aspect of the mine’s lifecycle.

Stage 1

Once a mineral deposit has been found, it is mapped and sampled to find out the size, grade and economic viability of the deposit. Planning and permitting: Work begins alongside local stakeholders, including governments and regulators, to plan the mine. We start looking at the layout, the costs, environmental management plans and we obtain all the necessary permits and approvals.

Stage 2

This is the build phase. We bring in the infrastructure and facilities to support mining operations, including utilities, processing plants, waste disposal facilities and access roads.

Stage 3

This is when a project becomes an operation. The extraction of the ore begins using heavy equipment such as excavators, haul trucks and drills. It’s then transported to processing plants for further treatment to extract the desired minerals. The operation phase of a mine can last anywhere from 20 to 50 years.

Environmental stewardship and community engagement are essential for the success of our projects and operations. We can only succeed when we look after the people and the places where we operate. For us, this means creating programmes in partnership with the local community. It means creating jobs and providing training to help people take those roles on. And it means working alongside local governments and leaders to find ways to ensure we’re looking after the environment too.

We hire and train experts, helping every colleague to achieve their full potential. Our lean culture provides the freedom to help us grow and shape our own careers. If you’re looking to start your career, we have fantastic learning opportunities. Careers at First Quantum are as diverse as the locations we work in around the world.

Sign up to receive updates with insights and stories from around First Quantum, our operations, our projects and our communities.

Sign up